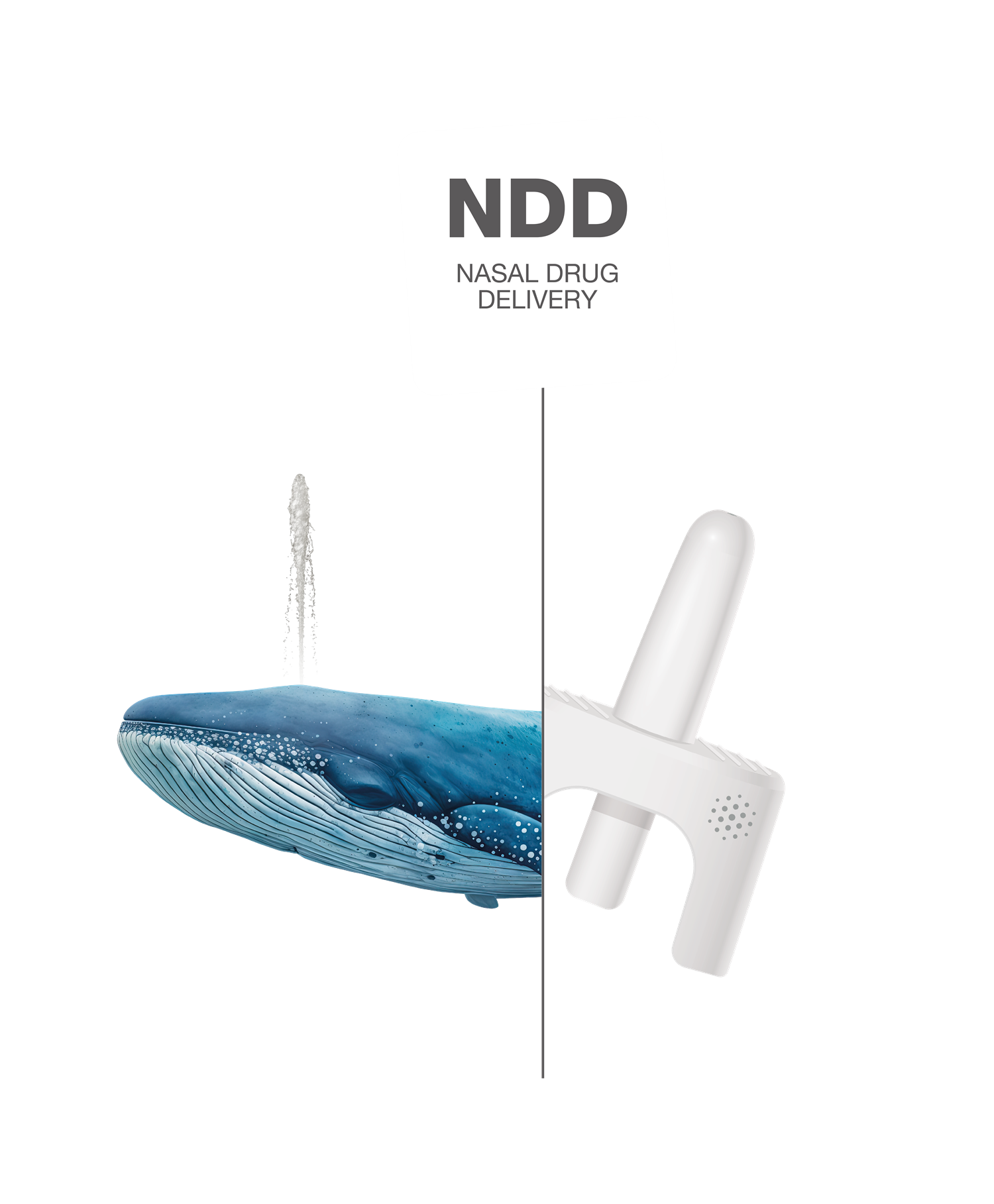

Breathing innovation into nasal drug delivery

Key services for pharmaceutical partners

Key benefits for patients

Aseptic Filling

In the manufacturing of sterile injectable drug products, quality and safety are paramount. Pharma companies must be able to rely on a trusted partner with the knowledge and capabilities to deliver service excellence in compliance with the latest regulatory standards.

At LTS, we have the capacity, expertise and experience to support a full spectrum of aseptic processing and sterilization services for products including small molecules, biologics, controlled substances (DEA Schedule I-V).

Our modern filling operations integrate advanced contamination control strategies and highly automated systems for inspection and packaging, ensuring consistent quality, efficiency, and reliable product release. Each year, multiple inspections by customers and international regulatory agencies confirm our adherence to the highest standards – reinforcing our proven track record in sterile injectables.

Features of filling lines

Our core products

Our capabilities span both development and commercial scale manufacturing of unit dose, bi dose, and multi dose nasal sprays, all produced in state of the art, environmentally controlled facilities. With a strong track record of regulatory approvals, we can seamlessly onboard projects at any point in their lifecycle—from early concept development and formulation optimization to clinical manufacturing and the transfer of established commercial products.

Micro Dose nasal spray

Unit-dose nasal spray

This patient-ready, primeless device precisely delivers a single dose via one-handed actuation. The drug product is filled and secured within a speciality micro glass vial prior to product assembly, with a standard 100μl (microliter) dose. Micro Dose is suitable for both local and systemic therapies and can support effective lifecycle management strategies for existing brands through the addition of its simple, 360° functionality.

Bi-dose nasal spray

Enabling the precision delivery of up to 200μl of drug product to the patient via two nasal sprays. In the case of both the bi-dose and unit-dose products, vial stoppering is critical to device performance, and we ensure it is closely controlled through the provision of both mechanical and vacuum stoppering at clinical and commercial scale.

Multi Dose

Multi-dose nasal spray

Comprehensive manufacturing capabilities to support the production of multi-dose devices that consistently and repeatedly deliver an accurate measured dose. Our environmentally controlled filling facilities ensure both preserved and sterile (non-preserved) multi-dose formulations are catered for